We will never Compromise at Sake brewing.

We have always adopted a thinking process geared toward

the

tide of the future,

and have come up with ideas and plans on the cutting edge,

worthy of Okunomatsu.

Beyond this, we contribute to the community, culture and to

our customers,

and aspire to make "Okunomatsu" the chosen

brand of Japanese sake.

seimai/senmai(精米~洗米)

The outer portion of the rice is ground away to remove fats and proteins

that lead to off-flavors. At Okunomatsu we mill 100% of our rice ourselves.

The rice is washed next. The timing, whichi in feeling of the hand is lifted form the water,

is decided. The expert manages the rice small-scale.

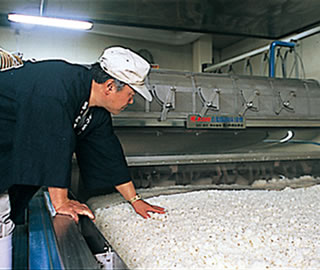

musimai(蒸し米)

The rice is steamed to make it easy for enzymes in the Koji mold to break down the starches.

We must steam the rice outside hard and inside soft.

In the steps of the sake-brewing process, Okunomatsu uses many up-to-date

equipments and thinking of the human who make it.

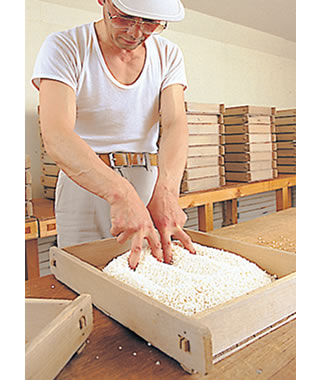

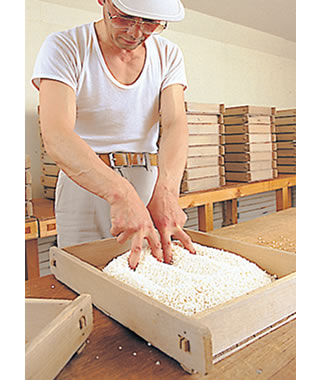

koji(麹)

Making koji is an important step that is really the key to making good sake.

In the cold air of winter, the rice is carried into the koji-making room.

The koji-making room becomes a stage for the dramas that unfolds between the brewers,

the rice, and the micro-organisms involved.

moto(酛)

In the small tank used for the yeast starter, koji converts starch into sugar.

Yeast then takes that sugar an eats it, giving of alcohol.

The master brewer gently watches over the fermenting mash like a mother,

trying to maintain an environment that allows for optimum conditions to promote the work of natures mysterious micro-organisms.

moromi(醪)

Once the yeast starter is ready,more steamed rice, koji and water are added to it in three stages.

Starch is being converted to sugar is being converted to alcohol at the same time in the same tank.

This is known as "multiple parallel fermentation".

sibori(搾り)

The yeast that works so hard to create the alcohol slowly sops working once that work is

finished.

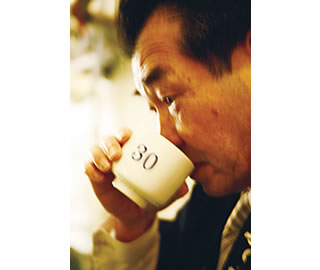

When the master brewer decides based on a combination of his sense and hard data that

fermentation is nearing confirmed.

At long last, the time for the sake to be born has been determined.

binzume(瓶詰)

Once all the steps have been completed, the sake is ready to be bottled.

Okunomatsu uses a piece of equipment called a Pasteurizer that is rarely used in the sake brewing industry, bottling, and a bacteria-killing hot water shower are all done in a clean room.

The newly-pressed sake, still rough and young, sits to allow sediment to drop,

The newly-pressed sake, still rough and young, sits to allow sediment to drop,